|

Maximize your confidence in SBE Builders with our complete

understanding of the components that made up structural wood shear

wall panels.

Structural Shear Wall Panel Construction variables:

How well is the wall put together? All of our framing is

tight and secured at each end with a structurally engineered hold-down unless U.O.N. on the structural plans.

Are there nails missing? All of our structural shear

walls are marked off at the structural engineers' required nailing

pattern for the allowable shear force in pounds per foot.

6-12 : 4:12 :

3:12 : 2:12 The marks on the structural shear wall plywood panel

help us precisely place the nails at the correct nailing pattern

resulting in the correct

number of nails per sheet. With the correct number of nails per sheet

the allowable shear force in pounds per foot for wood structural

panels is archived.

Are nails hitting the studs correctly? All of our structural

shear wall plywood panels have caulk lines centered on each stud

for precise nailing, eliminating shiners.

Are nails overdriven? We use nails guns with positive

placement fittings to ensure the nails are set at the correct depth.

If the nail is over driven, more than 1/32" below the surface of the panel,

due to a soft spot in the plywood we drive another nail next

to the over driven nail.

Are there gaps in the sheathing? We use an 1/8" gap

at all panel edges to reduce plywood panel edge swelling per the APA. We use an 1/4" gap

at all 4'x10' panel edges to reduce plywood panel edge swelling per the APA.

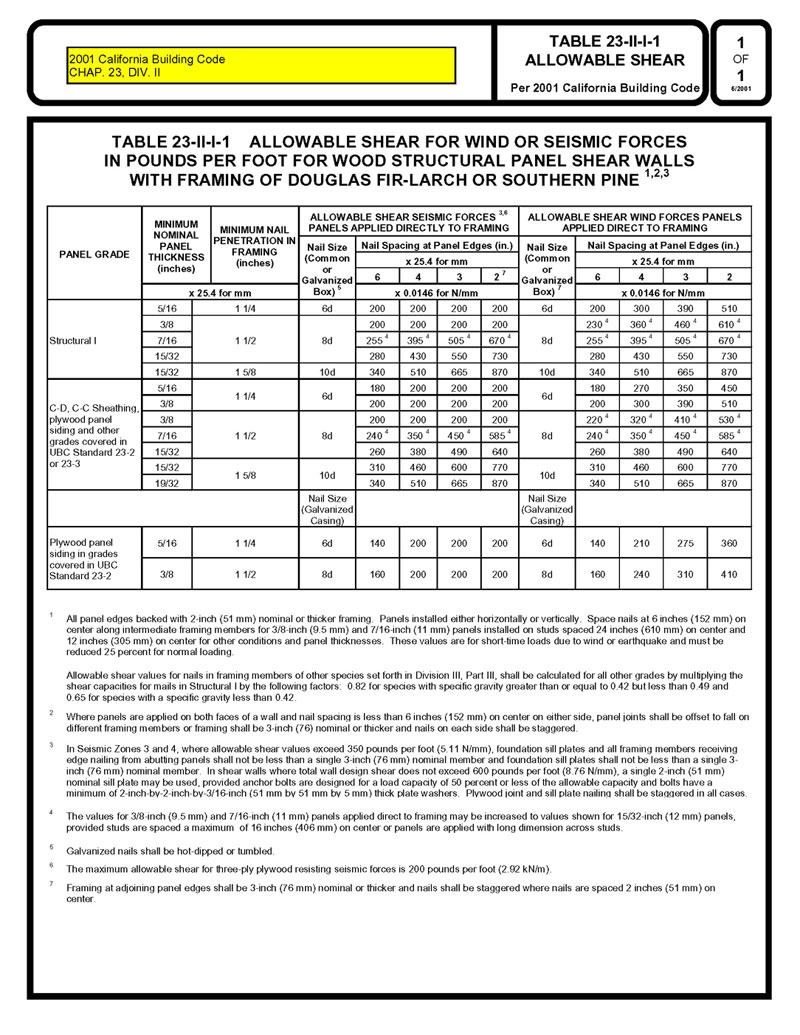

Are the nails penetrating the framing members correctly? We

use a minimum of an 2 3/8"

gun nails that result in a minimum of 1 5/8" nail penetration into

the wood framing member, which is also the UBC & CBC code minimum requirements

in Table 23-II-1-1 for allowable shear force in pounds per foot.

We do not use 10D shorts, 2 1/8" x .148.

The 10D shorts have been tested by the University of California

- Irvine and other structural engineers and have shown nails exhibited

about 5% less maximum shear load due to nails withdrawing from

the framing

under cyclic loading.

Are the nails the correct type and diameter? We

use hot dipped galvanized gun nails that result in better nail gripping

power and don't rust out, U.O.N. on the structural plans. All

of our shear walls and wall bracing panels nails are 10d x .148,

that results in better nail gripping

power and do

not withdraw from

the framing

under cyclic loading

like the .131 8d nails do.

The 10d x .148 also have less fastener fatigue failures under cyclic loading.

Are shear wall panels the correct type of plywood or OSB? All

of our structural shear wall plywood panels are CDX Douglas fir-larch

APA rated sheathing Struct 1 Group 1 with a span rating of 32/16

unless U.O.N.

on the structural plans.

If the structural plans call-out Struct 2 we will still use 5 ply

CDX at a minimum. We don't use OSB for shear walls because of the

swelling and nail popping associated with OSB plywood. There are

earlier and more extensive fastener fatigue failures in the

cyclic load shear wall tests with OSB than with CDX plywood. This

is due to higher density strength

in OSB than

CDX plywood. It is theorized that denser OSB sheathing deforms

less along the nail shank in contact with the sheathing, creating

a "fixed end" condition on the fastener. As a result, higher

internal bending stresses in the nail shank may develop at locations

below the surface of the wood framing, thus causing earlier fatigue

failures of the fasteners under cyclic loading. If the fasteners

don't fail than there's more potential of panel edge tear out

with OSB.

Are the allowable shear force in pounds per foot for wood structural

panels archived? Yes, all of our structural shear wall panels

archive the code minimum requirements in Table 23-II-1-1 for allowable

shear

force in pounds per foot.

By using Struct 1 plywood and 10d nails our wood structural panels

meet the allowable shear force in pounds per foot.

.

|